HOTSPIN®

Heated Laboratory Centrifuge

is also available as a complete heated liquid-liquid-solids test laboratory for on site sample testing up to +100°C / +212°F

Typical users are:

- Separation equipment users

- Separation equipment manufacturers

- Test laboratories

- Oil and gas exploration

- Tank farms

- Mineral oil and gas production plants

- Grease manufacturers

- Vegetable oil plants

- Animal fats plants

- Waste oil collectors and treatment companies

The HOTSPIN® is also used to simulate the conditions in a full size separation system using centrifugal separators.

The HOTSPIN®

is designed to perform accurate separation tests. The main use is to determine the water and sediment content in oils and fats, where increased temperature is necessary in order to lower the oil/fat viscosity so that proper separation can be achieved.

The HOTSPIN®

is designed to operate at up to 3000 rpm. with the HOTSPIN® glass tubes at a temperature of up to +100 °C / +212 °F. The HOTSPIN® works in accordance with ASTM D 1796 or API methods modified to use 10 ml glass tubes.

MK5

MK5 with control unit separated from the centrifuge is useful when spinning substances producing smelly gases at high temperatures like crude oils. The centrifuge can then be placed in a ventilated cabinet and the controlunit is kept outside. It comes with a 2m long

cable between centrifuge and control unit.

Available Models

Power supply 115V, 50/60Hz, 8A or 230V, 50/60Hz, 4A.

HOTSPIN® accessories

Operating Kit

One basic operating kit containing all necessary items to perform HOTSPIN tests including:

- 42 glass tubes. Type 1: twelve pcs. types, 2 -7: five pcs. each.

- One set, tube cleaning equipment

- One set, sample measuring and dosing devices

- One set, gear for personal protection

- One set, special tools and spare parts for the system

Transport case

The transport case is custom built to fit the HOTSPIN® centrifuge MK5 including the controlbox and the manual or MK5C including the operating kit.

Case dimensions and weight

- Width: 780 mm

- Depth: 530 mm

- Height: 340 mm

- Weight: 15 kg (empty)

- Weight: app. 45 kg (packed)

It is fitted with wheels at one end and has three handles for easy transportation.

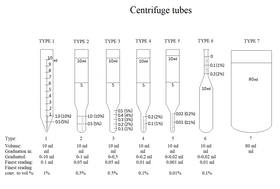

Glass Tubes

Centrifuge glass tubes.

The tubes are differently graduated and serve different purposes.

Please refer to the detailed picture of the tubes below,

or download our .png here

Or click the image to enlarge