MK5 with control unit separated from the centrifuge is useful when spinning substances producing smelly gases at high temperatures like crude oils. The centrifuge can then be placed in a ventilated cabinet and the controlunit is kept outside. It comes with a 2m long

cable between centrifuge and control unit.

MK5

with control unit separated

Power supply 115V, 50/60Hz, 8A or 230V, 50/60Hz, 4A.

MK5 Application and use

MK5 with the control unit separated from the centrifuge is useful when spinning substances producing smelly gases at high temperatures like crude oils. The centrifuge can then be placed in a ventilated cabinet and the control unit is kept outside. The units come with a 2m long cable between centrifuge and control unit.

If the liquid to be separated is not releasing volatile or smelly gasses at high temperatures, then our type MK5C with integrated control unit is the right choice. The MK5C requires less space and fits neatly on a bench top.

Both units are available packed in a travel case for onsite testing

We supply centrifuge tubes with various graduations as required, made of glass that withstand temperatures to up to +100 °C / +212 °F without any problem at 3000 rpm. They can be washed and repeatedly used.

A complete operating kit with various tubes, cleaning devices and accessories is also available.

A comprehensive section in the manual providing information on how to perform "HOTSPIN testing" and factors influencing the separation result.

The Hotspin system is especially suitable when;

- Quick and easy analysis are required

- Accurate heated centrifugation is required

- Sediment, water and emulsions contentin oils and fats shall be determined

- Checking emulsion stability, dosage and functions of emulsion breakers

- Checking flocculants stability, dosage and functions of flocculants

- Checking the function of full size centrifuges and filters in a process

- Scaling up to full size centrifuges

- Checking the quality of waste oil deliveries

- Checking the quality of a working process

- Etc.

The main features are:

- Built in accurate Heating for between ambient up to +100 °C / +212 °F, accuracy ±1°C

- Compact -low weight -easy to transport for field work. Transport box available.

- All electronic controls, motor without carbon brushes.

- Safety system with overheating and vibration cut out switch is included.

- Swing out rotor 90 degrees (centrifuge tubes rotate laying horizontally which provides accurate reading of the result against the tubes graduation)

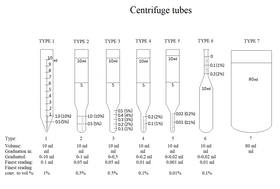

- 7 types Centrifuge tubes with different graduations are available

- All you need kit of accessories for sample testing, tube cleaning and personal protection to get started is available.

-Example: Checking oils and fats

The HOTSPIN is designed to perform accurate separation tests of oil/fat, water and sediment.

Typical use:

- Separate at elevated temperature from ambient to 100 degrees C / +212 °F

- Accurate determination of the oil/fat, water and sediment content in % by volume.

- To lower the oil viscosity by heating to determine at what temperature separation is possible/acceptable.

- To determine if, and what effect dosing of flocculants and emulsion breaking chemicals have on the separability.

- Simulate the conditions in a full-size separation system using centrifugal disc stack separators or decanter centrifuges.

- Check oil, emulsion, water and sediment content in waste oils, mineral and vegetable oils

MK5 Technical data

Description

The HOTSPIN is designed to perform accurate separation tests.

The main use is to determine the water and sediment content in oils and fats, where increased temperature is necessary to lower the oil viscosity so that proper separation can be achieved.

The HOTSPIN is also used to simulate the operating conditions in a full-size separation system using centrifugal separators.

The MK5 model has the control unit separated from the centrifuge with a 2 m long cable, thus the centrifuge can be placed in a ventilated cabinet while the control unit is outside.

The Centrifuge chamber is sealed off with rubber seal rings. The motor chamber is ventilated to cool and to ventilate out any volatile gas.

NOTE!!

The centrifuge and control unit is not Ex-proof, Spark proof, Water proof and not intended for operation in explosion-endangered area.

The HOTSPIN is designed to operate at up to 3000 rpm. with suitable glass tubes at temperatures of up to +100 °C / +212 °F

The HOTSPIN works in accordance with ASTM D 1796 or API methods modified to use

10 ml glass tubes.

Basic technical data/features

- Swing out rotor: Distance from rotor center to tube tip, radius 150 mm

- Variable speed: Electronic display 0-4000 rpm, in steps of 100 rpm.

- Relative centrifugal force: 0-1500 x g

- Centrifugation temperature: Electronic display, ambient to +100 °C / +212 °F, accuracy ±1°C

- Timer: Electronic setting 0-99 min in steps of 1 min, counting down.

- Imbalance cut off: Yes

- Operators safety: Equipment is built to European safety standard and is furnished with CE-marking.

- Centrifuge Tubes: Six types, volume 10 ml, with different graduations

finest graduation 0,001 ml corresponding to 0,01 %.

One type, volume 80 ml for sample collection.

- Accessories: Set of accessories for sample testing, tube cleaning and personal protection is available.

- Compact-low weight: The centrifuge is a bench top machine measuring only 380 x 450 x 260 mm, weighing only 27 kg.

Separate control unit 390 x 300 x 120 mm 7 kg

- On site field testing: The unit is suitable for transport. Transport case with wheels for on site analysis is available. 780 x 530 x 340 mm 14 kg

- Power supply: As per order: 230V 50 Hz or 115 V 60 Hz

HOTSPIN® accessories

Operating Kit

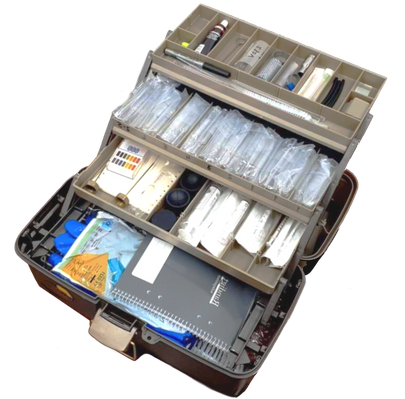

One basic operating kit containing all necessary items to perform HOTSPIN tests including:

- 42 glass tubes. Type 1: twelve pcs. types, 2 -7: five pcs. each.

- One set, tube cleaning equipment

- One set, sample measuring and dosing devices

- One set, gear for personal protection

- One set, special tools and spare parts for the system

Transport case

The transport case is custom built to fit the HOTSPIN® centrifuge MK5 including the controlbox and the manual or MK5C including the operating kit.

Case dimensions and weight

- Width: 780 mm

- Depth: 530 mm

- Height: 340 mm

- Weight: 15 kg (empty)

- Weight: app. 45 kg (packed)

It is fitted with wheels at one end and has three handles for easy transportation.

Glass Tubes

Centrifuge glass tubes.

The tubes are differently graduated and serve different purposes.

Please refer to the detailed picture of the tubes below,

or download our .png here

Or click the image to enlarge

HOTSPIN® Operating kit

One basic operating kit containing all necessary items to perform HOTSPIN tests including:

42 glass tubes. Type 1: twelve pcs. types, 2 -7: five pcs. each.

One set, tube cleaning equipment

One set, sample measuring and dosing devices

One set, gear for personal protection

One set, special tools and spare parts for the system

The use of the Operating kit will facilitate the work with the HOTSPIN® centrifuge.

A detailed list of all contents can be found here

The transport case is custom built to fit the HOTSPIN® centrifuge MK5 including the controlbox and the manual. The operating kit is carried separately.

Case dimensions and weight

- Width: 780 mm

- Depth: 530 mm

- Height: 340 mm

- Weight: 15 kg (empty)

- Weight: app. 45 kg (packed)

It is fitted with wheels at one end and has three handles for easy transportation.